“Removing water through drying or evaporation is an effective way of preserving many foods.”

Drying is the oldest and commonly practiced method of preserving food. Compared with other methods, drying is quite simple. In fact, you may already have most of the equipment on hand.

Drying reduces the moisture content of the food which in turn prevents spoilage by microorganisms. One of the biggest advantages of dried foods is that they take much less storage space than canned or frozen foods.

The choice of drying method depends on

01.Type of Feed and its heat sensitivity

02. Amount of Moisture

03.Drying kinetics

Methods of drying & their application

The removal of water from the food material during drying can be achieved in different ways. Some of them include:

- Oven Drying – For bread, cookies, cake, and other desserts

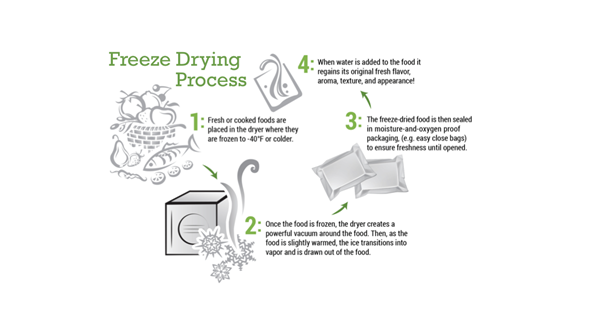

- Freeze Drying – For seasonal fruits, vegetables, & protein hydrolysates

- Spray Drying – For milk powder, coffee, flavorings & spices

- Drum Drying – For starches, breakfast cereals, & baby food

- Vacuum Drying – For malt based foods & ice cream crumbs

“Drying technologies are chosen to maximize product throughput, limit thermal damage, and provide reasonable costs.”

Here are the basic steps involved in the production of milk powder using spray dryer:

1. Separation and standardization of the raw milk

2. Pre-heating

3. Evaporation

4. Spray Drying

5. Packaging

Novel Drying Technologies

A number of studies have explored and developed innovative technologies which take advantage of other physical phenomena (e.g., ultrasound, electromagnetic field, pressure) to overcome the limitations of conventional technologies.

Refractance Window Drying

It is a drying technique that utilizes the combination of the three modes of heat transfer (i.e., convection, conduction, and radiation) for a more energy-efficient drying process. The technology is suitable for producing dried products from liquid and semi-liquid foods.

Ultrasound Assisted Drying

The application of ultrasonic energy to assist drying of food materials has been explored by many scientists. Despite various studies, no commercial scale installation of the ultrasound drying technology has been reported to date. This is due to some technological challenges in achieving an efficient transmission of acoustic energy and the practical difficulties in adapting the technology at an industrial scale.

Packaging and Storing Dried Foods

Dried foods are susceptible to insect contamination and moisture re-absorption and must be properly packaged and stored immediately. Food processors can use glass jars, metal cans, boxes with tight fitted lids or moisture-vapor resistant freezer cartons to pack dried foods.

The storage temperature plays an important role in determining shelf life. Dried food is usually stored in cool, dark areas.

Fruit that has been sulfured should not be placed in metal containers directly. The dried fruit should be placed first in a plastic bag and then, stored in a metal canister.

Click Here to Download PDF